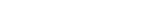

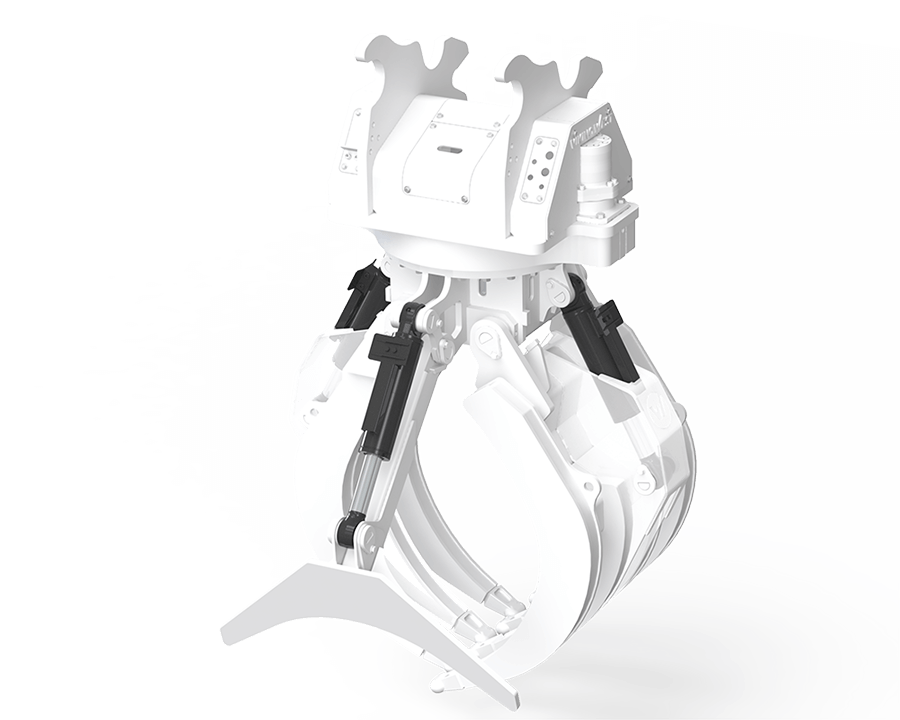

GRAPPLES

Power Clam

Your loader is the heart of your logging operation, so you need a grapple that supports maximum productivity. With a Viking West G-Series power clam grapple on your loader, you can count on exceptional performance in the most demanding forestry conditions.

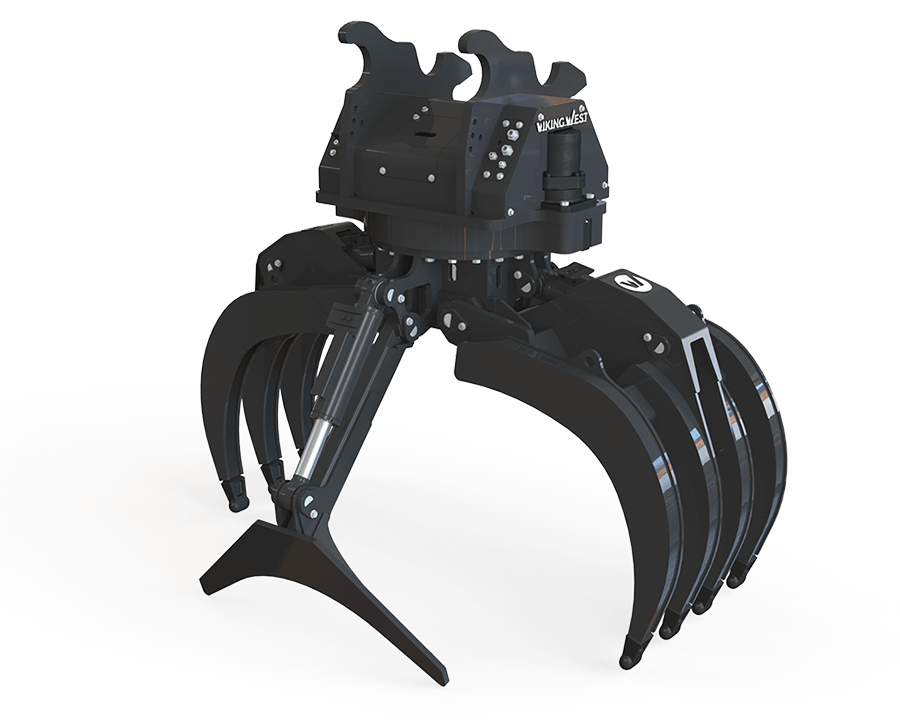

Forestry grapples are expected to handle extreme loads in the toughest conditions. We spend countless hours testing our G-Series power clam grapples in real-world conditions to ensure that they won’t let you down. In addition, detailed analysis of strain gauge results ensure that our finite element analysis models are accurate and our trouble-free life predictions are reliable.

Our G-Series power clam grapples are designed for maximum flexibility. Whether you are looking for 8, 10 or 12 cubic foot jaws, planning to attach to your carrier with wedge lock or direct pin on lugging, or wanting to use our standard fixed outriggers or optional hydraulic outriggers to handle full-length timber, these options are easy to configure at the time of order or implement later when the need arises.

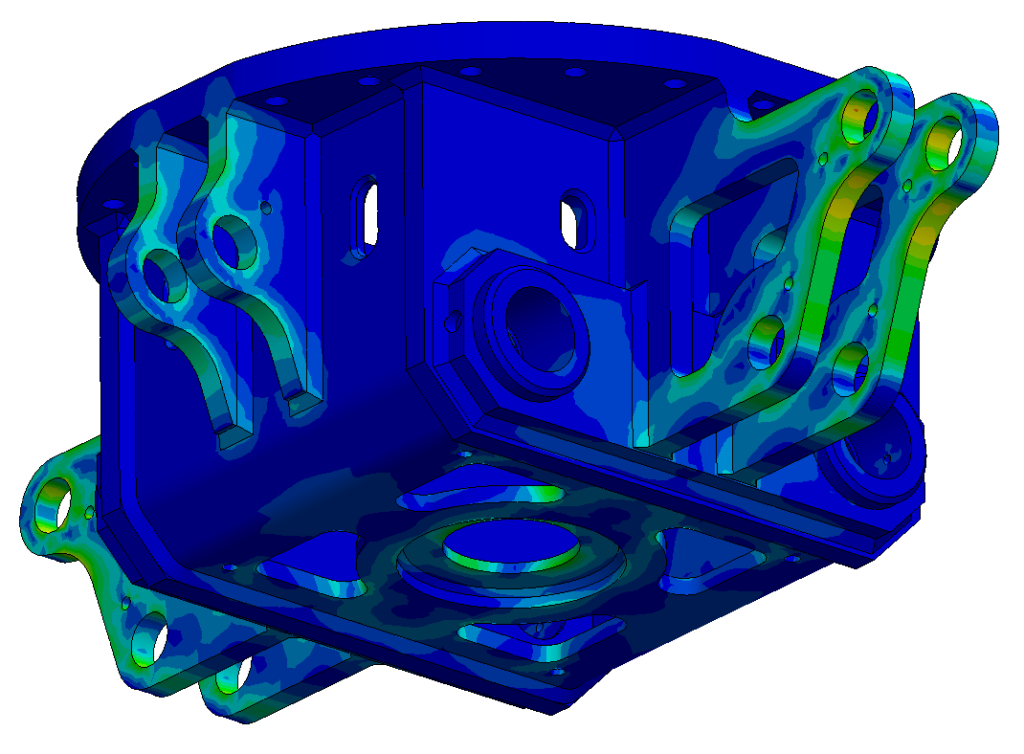

Moving wood faster means increased demands on your grapple and dramatically increased forces on the main bearing. Viking West is the first grapple manufacturer to provide a heavy-duty double-row main bearing, which comes standard on all G-Series power clam grapples.

Our thumb cylinders are designed and individually proof tested to 5800PSI for use with modern excavator high-pressure hydraulic systems.

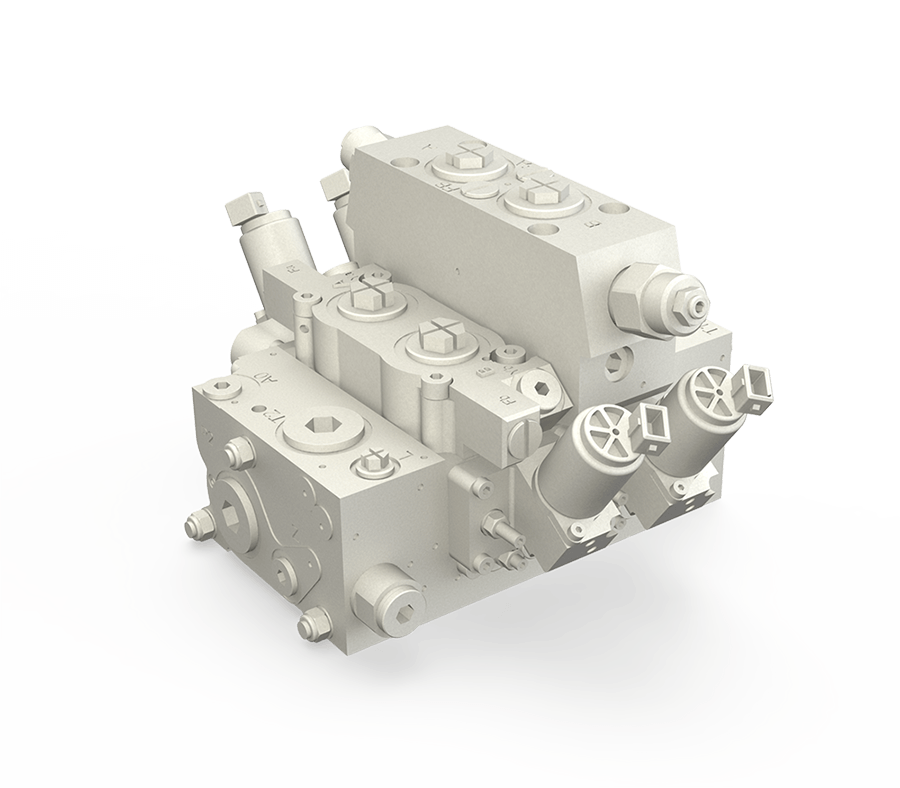

Our G-Series power clam grapples feature an AMCA control valve, which has a superior design for high-vibration applications. This valve utilizes precision dowels to lock individual sections to each other, thereby greatly reducing susceptibility to leaking between sections caused by vibration and mounting surface flex.

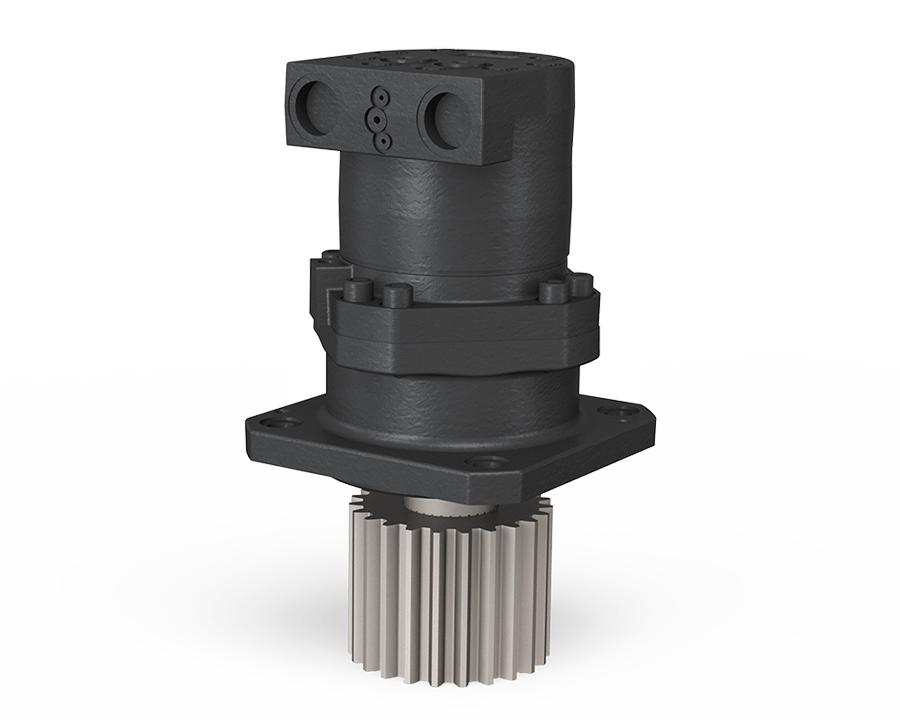

Our G-Series power clam grapples feature dual Eaton VIS motors complete with precision ground drum profile pinion teeth for optimal tooth loading and extended life.

Our bull nose grapple tips minimize damage to timber during loading, thereby protecting the value of your timber and are easily replaceable in the future if you wear them out.

Every Viking West G-Series power clam grapple comes with an industry-leading 24-month warranty. If you need our support, we promise to have service parts in stock and qualified technicians available to get you back up and running.

Product Options

200 Series Hydraulic Quick Coupler

Product Overview:

Viking West Hydraulic Wedge couplers enable you to quickly attach, detach and share compatible attachments amongst your fleet from the comfort of your cab. You will appreciate our unique design features that ensure safe, reliable and flexible operation to minimize downtime and maximize your productivity

ISO13031:2016 compliant – Viking West hydraulic wedge quick couplers comply with the latest requirements of ISO13031 International safety standard for earth-moving machinery quick couplers

Easy operation from cab – Rocker switch with momentary actuator integrated into operator’s console for safe and convenient activation of primary wedge lock and secondary pin lock from cab.

Fail safe design – Primary locking cylinder and secondary pin lock have fail safe design in event of system pressure loss

Visual indicator for lock engagement – Safe lock position is visible from cab so operator can work confidently knowing his attachment is secure

Easy conversion to manual operation – Coupler can be easily converted from hydraulic to manual operation in event of hydraulic system malfunction.

Induction Hardened Bushings – Induction hardened high-strength steel for replaceable bushings to ensure long term durability and serviceability

Peace of Mind – Every Viking West hydraulic quick coupler comes with an industry-leading 24-month warranty. If you need our support, we promise to have service parts in stock and qualified technicians available to get you back up and running.

Specifications:

| Series | 200 |

| Lugging Style | WBM Wedge Lock |

| Width (mm/in) | 520/20.5 |

| Length (mm/in) | 1136/44.7 |

| Height (mm/in) | 345/13.6 |

| Weight (kg/lb) |

200/440 |

| Pin Diameter (mm/in) |

80/3.1 |