PRODUCT UPDATE:

Quick coupling systems have revolutionized the way workers approach excavation by increasing productivity without compromising health and safety. Viking West’s hydraulic wedge lock quick couplers are made with versatility at the forefront of the design and are compliant with the requirements set by ISO 13031 International Safety Standard.

With this next generation of hydraulic couplers, operators can get more work done within a smaller footprint, all while ensuring the security and longevity of their attachments.

The Safety Standard

Before we dig into the details of Viking West’s hydraulic quick couplers, let’s outline the safety standard. An ISO 13031:2016 compliant quick coupler must:

- Allow the operator to pick-up and lock attachments from within the cab.

- Make it easy for the operator to clearly see that the attachment is securely locked in place, without having to leave the cab.

- Keep the attachment secure, even if unintentional damage to hydraulics, or the coupler itself, should occur.

- Safely release attachments from within the cab, without any manual operation from outside the cab.

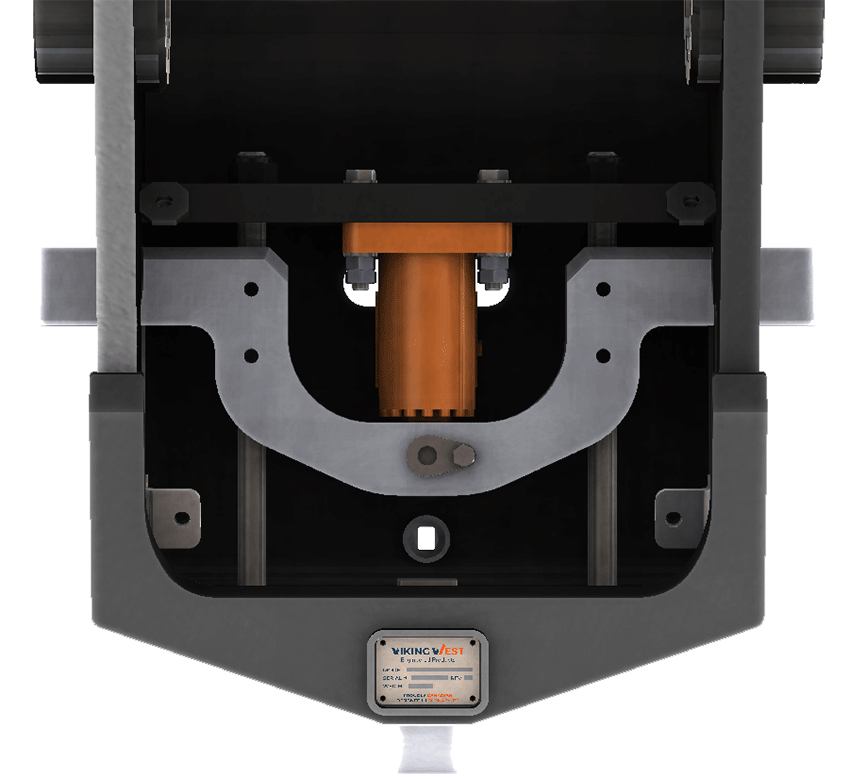

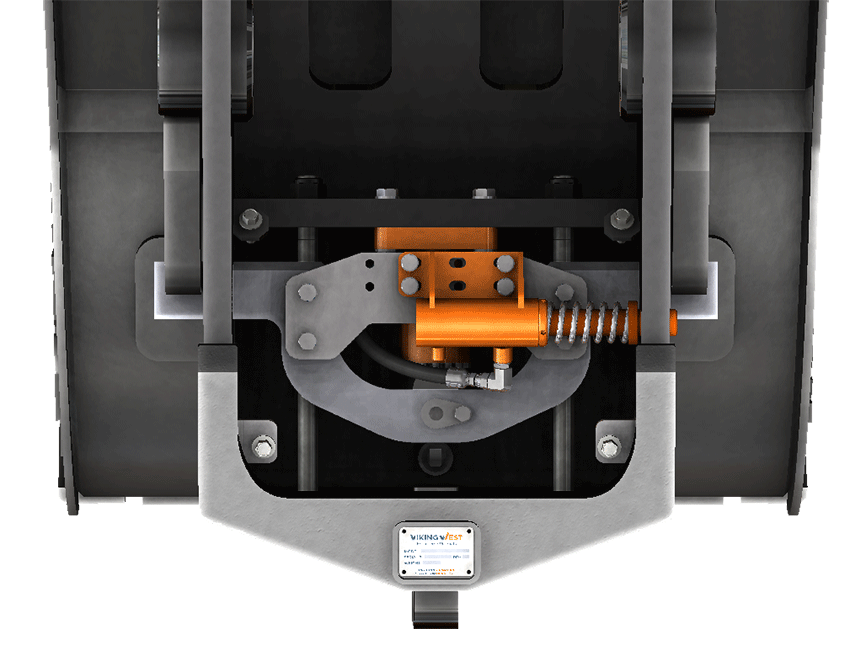

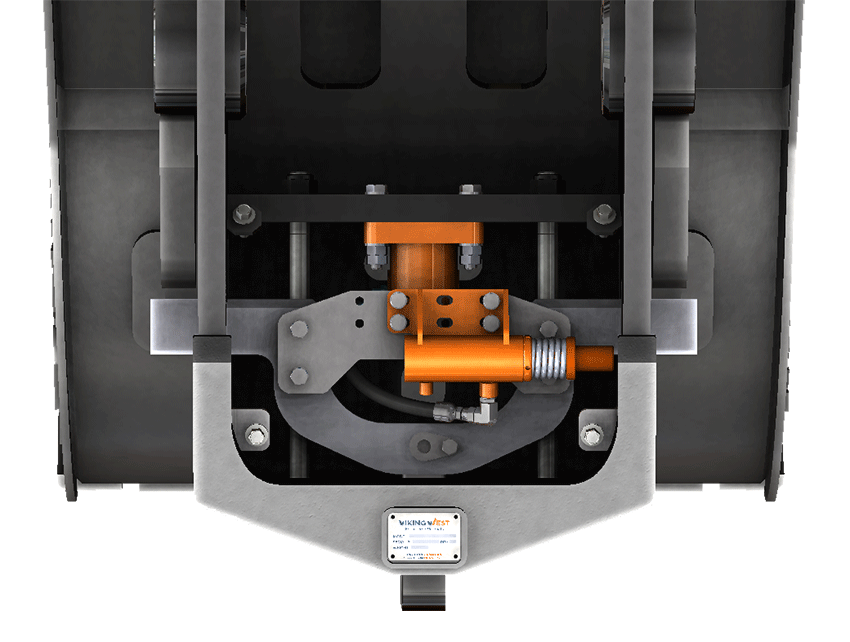

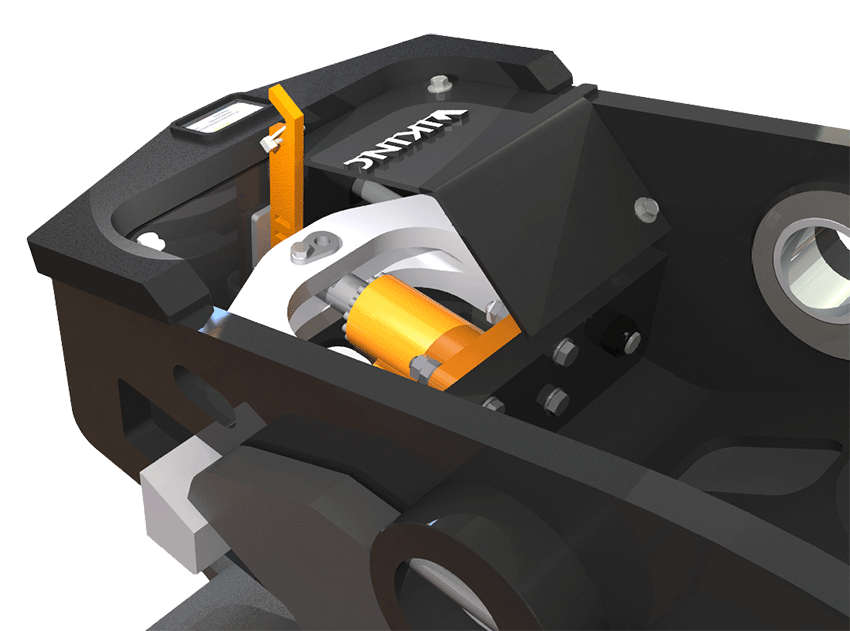

Product Visualization

How Viking West Hydraulic Wedge Lock Quick Couplers work

Viking West hydraulic wedge lock quick couplers utilize a forced-lock engagement system, which is activated by a rocker switch found on the console, within the cab. These couplers use a main hydraulic cylinder to position the wedge bar, providing the holding force necessary to prevent release.

Once the wedge bar is engaged, a secondary hydraulic locking cylinder is activated. This drives a locking pin through a keyhole in the body of the coupler. This system is required to prevent disengagement of the wedge bar, ensuring the attachment stays secured in place. Viking West’s design is fail-safe, even in the event of a system pressure loss.

Viking West’s locking pin is painted with high visibility orange. As the locking pin passes through the keyhole on the cab-side of the coupler, it can easily be seen from the operator’s seat inside the cab.

Additional Safety Features

To mitigate the risk of the operator unintentionally activating the rocker switch on the cab console, Viking West has implemented two safety features. The first is a momentary actuator on the rocker switch. This requires the operator to unlock the switch before they can use it to activate the coupler. The second is an audible buzzer that sounds when the switch is in the activated position.

Curl and Go

One of the key safety features of Viking West’s hydraulic wedge lock quick coupler is the “Curl and Go” procedure. This is a pressure override event where the operator must curl the arm and bucket inward to actuate a safety valve in the manifold. This must happen before the lock cylinder will disengage, allowing the main cylinder to operate.

Fail-Safe Locking

Viking West hydraulic quick couplers have a fail-safe locking cylinder design. This includes a heavy-duty spring that holds the locking pin in a securely locked position and can only be compressed when the cylinder rod is retracted by hydraulic force. The locking pin will remain in the locked position until the electric signal to activate, and hydraulic force to retract, has occurred.

Equipped with heavy-duty lifting eyes, Viking West hydraulic wedge lock quick couplers are designed in accordance with ISO 20474-1, with a clearly-marked Rated Lifting Load (RLL), ensuring confidence in the coupler’s certified lifting capacity.

Unique Features

Why a Viking West Hydraulic Quick Coupler is the Clear Choice

One of the main requirements in the design process was to ensure versatility. Viking West’s hydraulic coupler can be operated manually in the event that hydraulic pressure is lost or one of the hydraulic components is not functioning properly.

If the secondary locking cylinder is not functioning, the wedge bar can be locked in place with the manual locking bar provided.

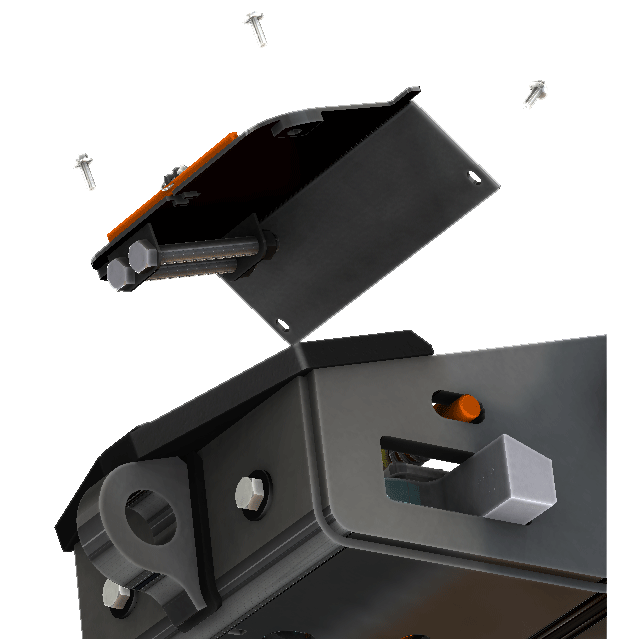

Image of back-up bolts that can be used to replace wedge bar guide rods and enable manual movement of wedge bar in same fashion as manual wedge lock couplers.

Back-Up Bolts

If the main cylinder is not functioning, hex head bolts are provided with the coupler. These enable manual movement and the ability to lock the wedge bar.

Viking West hydraulic wedge lock quick couplers come with a 24-month warranty. They comply with the safety standard set by ISO 13031:2016 and have multiple safety features including the fail-safe locking system, visual indicator for lock engagement and ISO 20474-1 compliant lifting eyes. These quick couplers are easily operated while safely inside the cab of the machine, with the ability to convert to manual operation as needed.

For more information on Viking West’s line of quick couplers, fill-out our online form or call us at 604-381-0929 or Toll Free 1-855-500-6607.